Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

The Ultimate Guide to Electrodeposition And Surface Finishing Techniques

Are you interested in learning about the fascinating world of electrodeposition and surface finishing? Look no further! In this comprehensive guide, we will delve into the intricacies of these techniques, exploring their applications, benefits, and the latest advancements in the field. Whether you are a scientist, engineer, or simply someone with a curiosity for metal coatings and finishes, this article will provide you with valuable insights and knowledge.

What is Electrodeposition?

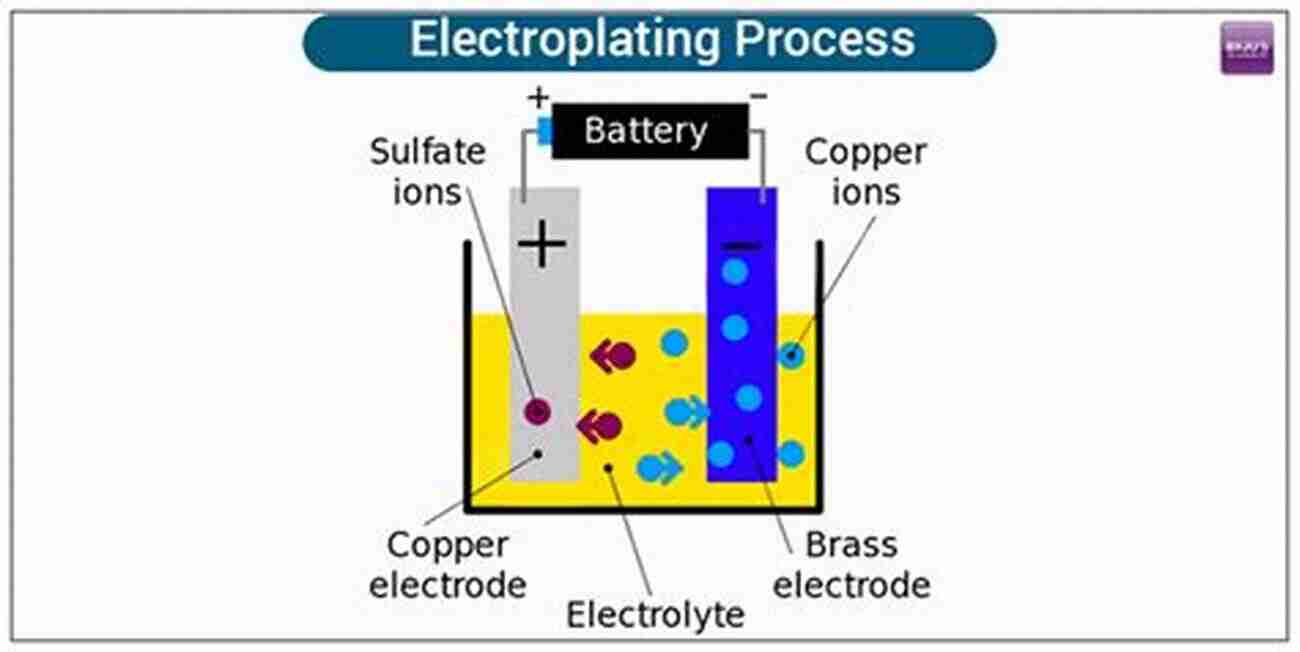

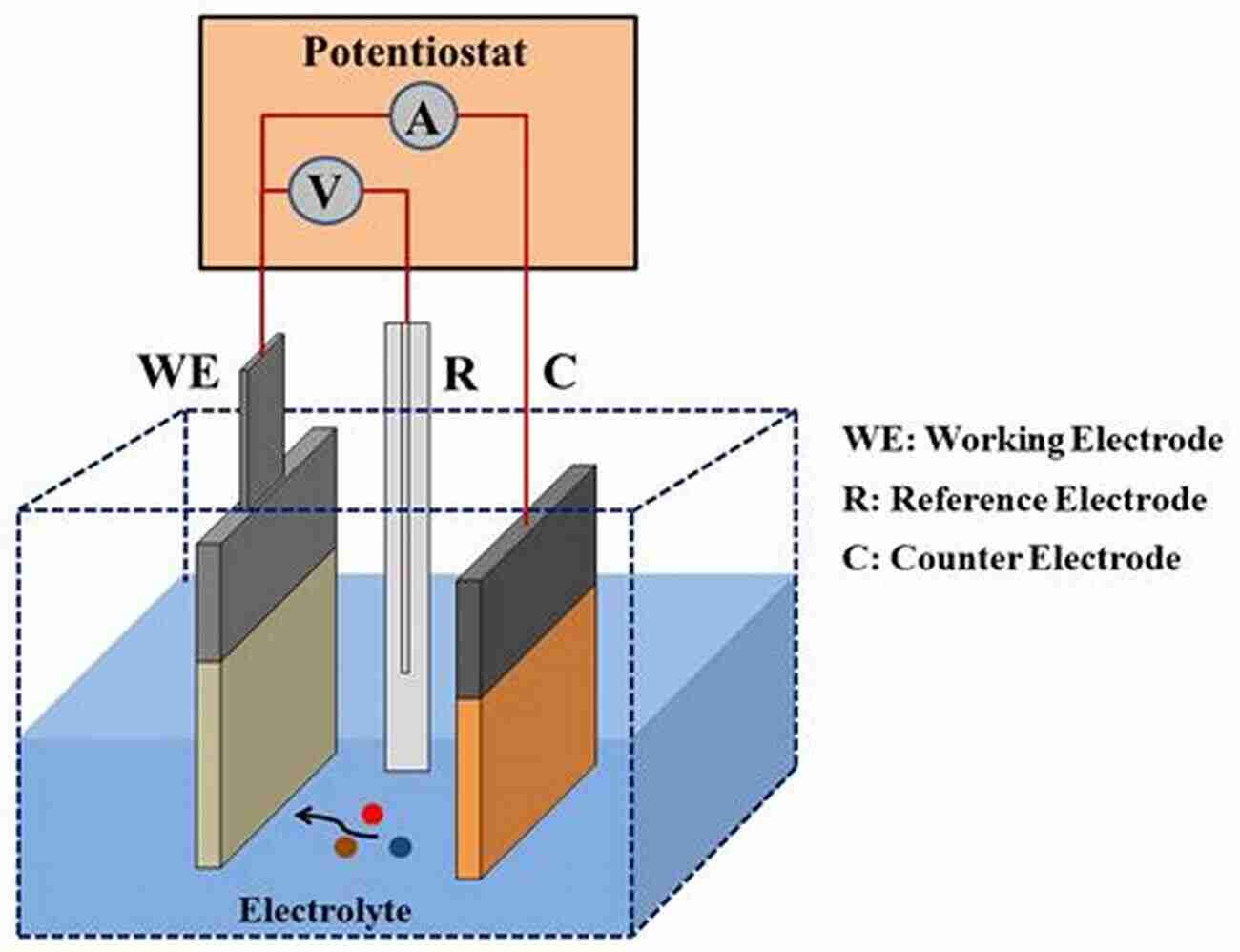

Electrodeposition, also known as electroplating, is a process that involves depositing a thin layer of metal onto a surface using electric current. This technique has been used for centuries to enhance the appearance, protect against corrosion, and improve the functionality of various materials.

The electrodeposition process begins with an electrolyte solution containing metal ions and a suitable electrode. The surface to be plated is used as the cathode, while the anode is made of the metal that will be deposited. When a current is applied, metal ions migrate towards the cathode and are reduced to metallic form, effectively forming a layer on the surface.

5 out of 5

| Language | : | English |

| File size | : | 15899 KB |

| Text-to-Speech | : | Enabled |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 600 pages |

| Screen Reader | : | Supported |

The advantages of electrodeposition are numerous. It allows for precise control over coating thickness, uniformity, and composition, making it suitable for a wide range of applications. Additionally, electrodeposited metal coatings exhibit excellent adhesion, durability, and resistance to harsh environments.

Surface Finishing Techniques

Surface finishing, on the other hand, refers to a collection of processes performed on a material's surface to alter its appearance, texture, or functionality. It includes various techniques such as polishing, buffing, sandblasting, anodizing, and electroplating.

One of the most commonly used surface finishing techniques is electroplating. As mentioned earlier, it involves electrodeposition to deposit a layer of metal onto a surface. Electroplating can create a wide range of finishes, including shiny, matte, brushed, or textured surfaces.

Anodizing is another surface finishing technique widely used for aluminum and its alloys. It involves creating an oxide layer on the surface, which improves corrosion resistance, hardness, and wear resistance. Anodized surfaces can also be dyed in various colors, offering additional aesthetic options.

Polishing and buffing are mechanical surface finishing techniques that involve abrasive materials to remove imperfections, scratches, or oxidation from a surface. These processes result in a smooth and shiny finish, making them popular choices for jewelry, automotive parts, and other metal objects.

The Future of Electrodeposition and Surface Finishing

The field of electrodeposition and surface finishing is continuously evolving, driven by advancements in technology, environmental concerns, and the demand for improved performance. Researchers and engineers are exploring new materials, developing more sustainable processes, and implementing innovative surface modification techniques.

One exciting trend is the development of nanoscale and nanocomposite coatings through electrodeposition. These ultra-thin coatings offer unique properties, such as enhanced hardness, wear resistance, and antimicrobial properties. They find applications in various industries, including electronics, automotive, and medical.

Another area of interest is the exploration of alternative electrodeposition methods, such as electroless plating and electrodeposition from ionic liquids. These techniques eliminate the need for external power sources, allowing for more efficient and cost-effective coating processes.

Environmental sustainability is becoming a key consideration in electrodeposition and surface finishing. Researchers are developing eco-friendly electrolytes, reducing the use of hazardous chemicals, and implementing waste management strategies. This shift towards greener practices ensures that these technologies are not only effective but also environmentally responsible.

Electrodeposition and surface finishing play crucial roles in a wide range of industries, from manufacturing to electronics and beyond. The ability to enhance the appearance, protect against corrosion, and improve functionality makes electrodeposition a versatile technique. Surface finishing, on the other hand, offers endless possibilities for altering the look, feel, and performance of materials.

As we have explored in this article, electrodeposition and surface finishing are continually advancing, leading to exciting discoveries and innovations. From nanoscale coatings to sustainable practices, these fields are poised to revolutionize various industries, ensuring that our future is brighter, more durable, and more aesthetically pleasing.

5 out of 5

| Language | : | English |

| File size | : | 15899 KB |

| Text-to-Speech | : | Enabled |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 600 pages |

| Screen Reader | : | Supported |

This volume of Modern Aspects of Electrochemistry has contributions from significant individuals in electrochemistry. This 7 chapter book discusses electrodeposition and the characterization of alloys and composite materials, the mechanistic aspects of lead electrodeposition, electrophoretic deposition of ceramic materials onto metal surfaces and the fundamentals of metal oxides for energy conversion and storage technologies. This volume also has a chapter devoted to the anodization of aluminum, electrochemical aspects of chemical and mechanical polishing, and surface treatments prior to metallization of semiconductors, ceramics, and polymers. This volume of Modern Aspects of Electrochemistry is ideal for scientists, researchers, engineers, and students interested in the latest findings in the field of electrodeposition and surface finishing.

Anthony Burgess

Anthony BurgessEverything You Need To Know About Building Referral...

Are you looking for ways to boost revenue...

Aleksandr Pushkin

Aleksandr PushkinThe Fascinating History of Afro Uruguay - Unveiling the...

Afro Uruguay refers to the rich and diverse...

Anton Foster

Anton FosterReflections From Stubborn Son: A Journey of...

Have you ever encountered a stubborn...

Brennan Blair

Brennan BlairDiscover the Revolutionary World of Protein Modelling:...

Protein modelling is an essential...

Ricky Bell

Ricky BellThe Best Old Fashioned Advice: Timeless Wisdom Passed...

Have you ever turned to your grandparents,...

Isaiah Price

Isaiah PriceEmbark on an Unforgettable Journey: The Sword and Sorcery...

Are you ready to be...

Hassan Cox

Hassan CoxThe Enchanting World of Wendy Darling Comes Alive in...

Step into the magical world of Neverland...

Ivan Turner

Ivan TurnerAdsorption Calculations And Modelling Chi Tien: Unlocking...

In the field of chemistry, adsorption is a...

Harvey Hughes

Harvey HughesUnleashing the Full Potential of a Team: How To Organize...

"Genius is 1% inspiration and 99%...

Desmond Foster

Desmond FosterThe Fascinating Journey of George Romanes: From...

George John Romanes, born on May 20, 1848,...

Adrien Blair

Adrien BlairThe Untold Truth: The Bible In The Early Church - A...

Lorem ipsum dolor sit amet, consectetur...

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

David PetersonThe Poetical Works Of George Macdonald In Two Volumes Volume: Unleashing the...

David PetersonThe Poetical Works Of George Macdonald In Two Volumes Volume: Unleashing the...

Mitch FosterThe Silent Suffering: A Black Man's Experience With Depression – Unveiling...

Mitch FosterThe Silent Suffering: A Black Man's Experience With Depression – Unveiling... Chuck MitchellFollow ·5.5k

Chuck MitchellFollow ·5.5k Cason CoxFollow ·18.2k

Cason CoxFollow ·18.2k Vincent MitchellFollow ·13.5k

Vincent MitchellFollow ·13.5k Efrain PowellFollow ·3.4k

Efrain PowellFollow ·3.4k Ashton ReedFollow ·7k

Ashton ReedFollow ·7k Blake KennedyFollow ·7.2k

Blake KennedyFollow ·7.2k Jeffrey HayesFollow ·2k

Jeffrey HayesFollow ·2k Chinua AchebeFollow ·11.9k

Chinua AchebeFollow ·11.9k